5-Axis Machining Shop Services

With the capacity to machine complex geometries and high repeatability, 5-axis CNC milling has become the standard machining option where high performance and complex components are required. With the capability to move all five axes simultaneously, 5-axis milling is well-suited for parts that cannot be made with any other milling machine.

As an ASD9100-certified manufacturer, Miller CNC creates performance-built components using various hard metals for superior results. We use advanced 5-axis milling to create complex parts for a variety of industries. We work directly with you to plan, engineer, develop, and inspect all CNC-machined components to provide you with precisely what you need.

Contact Miller CNC today to discuss our CNC machining capabilities and how we can best assist you.

5-Axis Milling vs 3-Axis Milling

5-axis milling is an advanced form of machining for fabricating custom parts. Derived from 3-axis CNC machining, 5-axis milling creates highly complex components at high-speed rates. 3-axis milling uses three main axes (X, Y, and Z) to manufacture simple parts, sharpen edges, or drill holes. 5-axis milling includes two additional axes, each with independent rotational capabilities. This independence allows all five axes to move simultaneously, supporting multidimensional processing and complicated rotational movements.

Miller CNC’s 5-axis CAM software with machine simulation allows all component features to be machined without physically handling the part in one setup. This allows for more accuracy than any other milling machine can provide. 5-axis milling offers an unmatched level of precision, machining components that comply with strict industry standards and requirements. Full automation capabilities allow for reduced set-up times and optimized cycle stages, resulting in enhanced efficiency, lower production times, and reduced costs.

What is 5-Axis Machining Used For?

Miller CNC has been trusted with government and defense contracts for more than a decade. In addition to machining components for the military and defense industry, we create performance-built components for a variety of industries, including:

5-Axis CNC Milling Services for Hard Metal Components

Our 5-axis machining services allow us to specialize in superalloy and hard metal components. Understanding the application needs of your industry means understanding the need for machined components that are lightweight, rugged, and can withstand extreme temperatures without losing performance or structural integrity. Some of our machined products include but are not limited to:

- Bulkheads

- Fasteners

- Fuel Injection Components

- Fuel Valves

- Heat Sinks

- Hydraulic Actuators

- Pressure Control Units

- Shafts

- Solenoids

Contact Miller CNC today and learn what we can fabricate for you!

5-Axis Milling FAQs

What is 5-axis CNC machining?

5-axis CNC machining utilizes five independent axes rotating simultaneously to create highly complex geometries. This allows five sides of a part to be machined from a single fixture setup. 5-axis machining is the most advanced form of CNC machining and is best for complex parts that other machines cannot replicate. As an experienced 5-axis CNC machine shop, Miller CNC uses 5-axis milling equipment to fabricate high-precision components in one setup.

What is the advantage of a 5-axis CNC machine?

Operating all five axes simultaneously sets 5-axis CNC machining apart from other CNC milling services. All features of a component are machined in a single setup, reducing handling and improving production rates. 5-axis machining is the go-to method for fabricating high-quality components quickly and precisely.

What 5-axis milling equipment does Miller CNC use?

We operate advanced 5-axis machinery to fabricate high-performance components.

- Hermle, C400, 18K RPM 36x30x20 machining center

- Hermle, C30, 18K RPM, 30x20x20 machining center

- 2 Doosan, DNM-5AX, 12K RPM, 18x18x18 machining centers

- Haas, VF2, 10K RPM, 30x20x20 machining center

Miller CNC is Your Trusted 5-Axis CNC Machine Shop

Miller CNC is one of the industry's first and most experienced 5-axis milling machine shops. We can handle time-critical schedules and even the most complicated components. Our 5-axis milling centers, along with our advanced software, provide a best-in-class manufacturing experience.

At Miller CNC, we are committed to building long-lasting relationships with our customers. Contact us for more information, or request a quote to get started today.

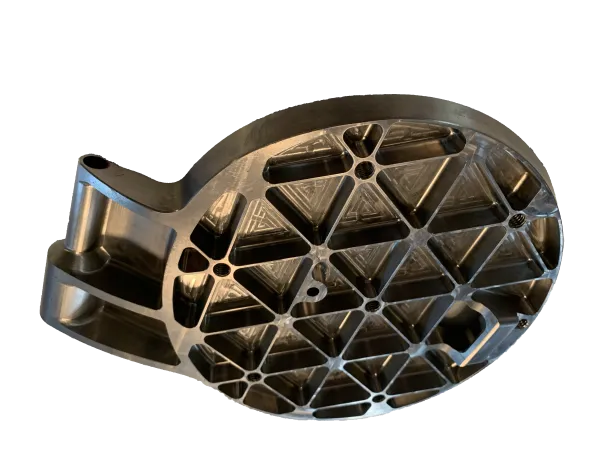

Complex 5 Axis Milled Titanium Part